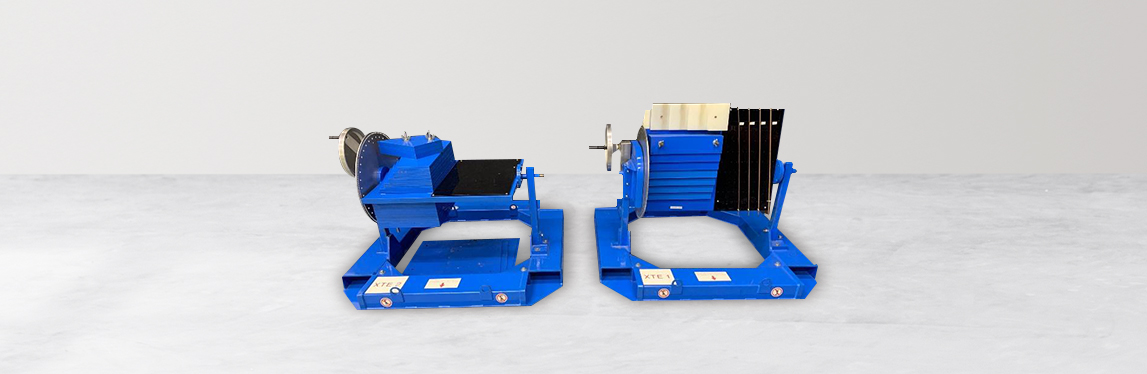

XTE™ Cargo

XTE™ Cargo

FEATURES & TECHNICAL SPECIFICATIONS

Suitable for X-Ray and Gamma Ray Cargo scanners from 1MeV to 9 MeV.

Typical users are OEM manufacturers, Customs Border Protection, CBP locations in seaports, rail ports and cross borders where large Non Intrusive Inspection, NII border scanners are to be tested for site acceptance and maintenance.

Due to its busy nature (mega ports), with hundreds of containers to be scanned per scanner per day a quick, no down time and accurate image quality evaluation is needed to maintain the scanners are working to specification throughout the lifetime of the scanner.

Universal (Any OEM)

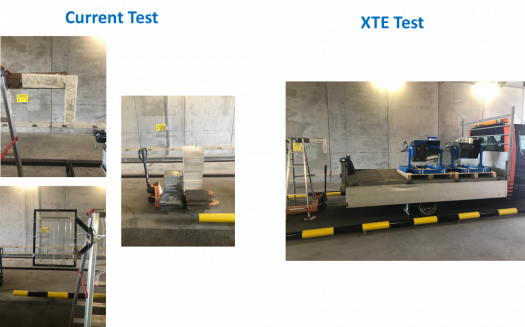

One Pass / 5 mins evaluation versus 2 to 3 days (typical)

No Downtime

Small Footprint (Forklift ready on 1mx1m pellet to be hoisted to truck)

Accurate Rotatable Mechanism (any x-ray angle)

9 Comprehensive Tests

Comparison Current Practice Versus XTE

9 Comprehensive Test

- Test 1 Resolution Test

Image Quality Indicator, IQI on sharpness and blurring of copper wire images in air and behind concealment

- Test 2 and 3 Material Discrimination Air

Organic test of several thickness of explosive surrogate in air

- Test 4 Contrast Sensitivity

Contrast is the measure of density difference between 2 areas. Easier to distinguish features of interest amongst its surrounding. The lower the sensitivity level the better

- Test 5 Material Discrimination Steel

Contraband and explosive test behind steel concealment

- Test 6 Spatial Resolution

The ability of image system to differentiate between 2 nearby objects. Typical thickness ranges from 6mm to 2mm

- Test 7 Material Discrimination

4 types of materials with various thickness are tested ranging from aluminum to organics

- Test 8 Spatial Resolution Concealment

- Test 9 Penetration

The level of penetration of system e.g. 250mm to 350mm steel