XTE™ Lite

XTE™ Lite

FEATURES & TECHNICAL SPECIFICATIONS

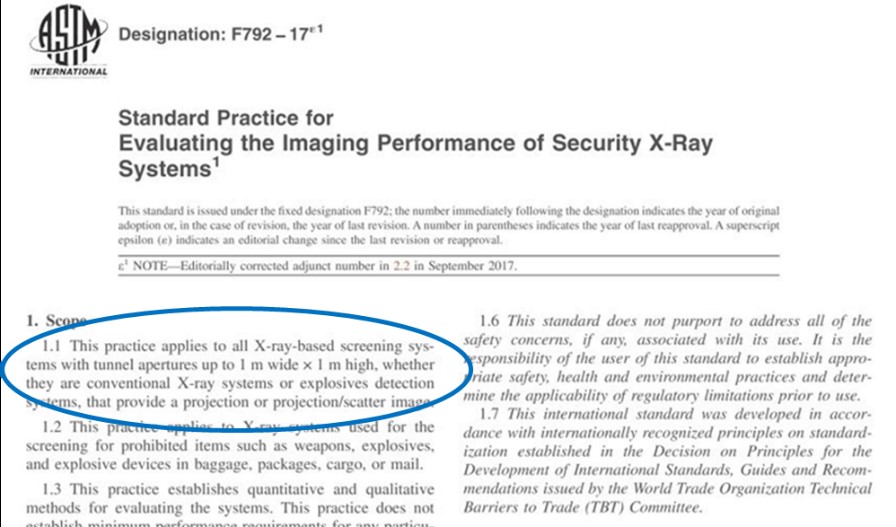

Suitable for X-Rays of 150keV to 450keV and tunnel size greater than 1mX1m.

Typical users are OEM manufacturers, air freight companies, airport authorities, airport baggage medium size check in counters.

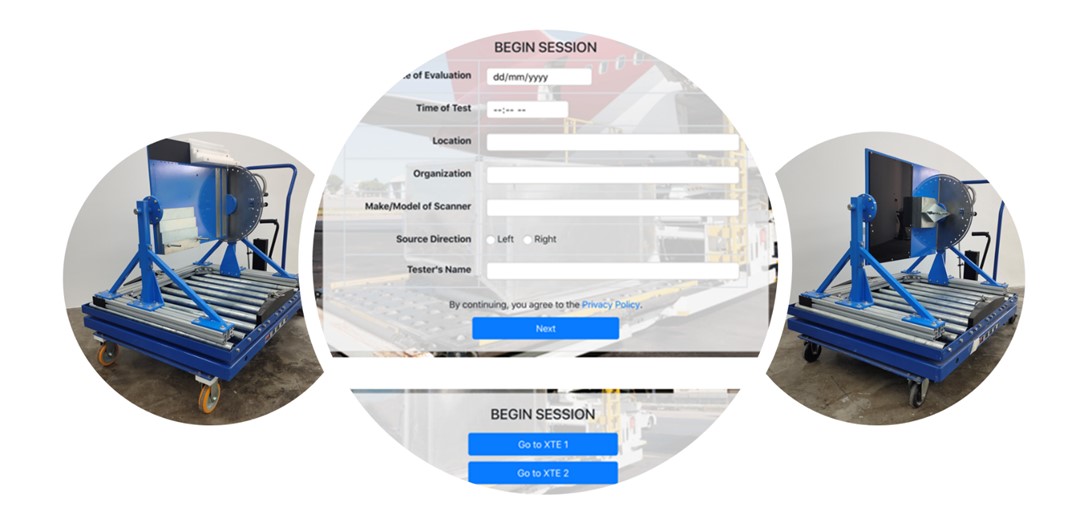

Currently the image evaluation tests are done using a Standard Test Piece, STP box on a structure (see picture below to prop up the test box typically for top down x-rays). XTE™ Lite does not need any structure and our test plane is completely devoted for testing. It can be angled at every 2 degrees instead of just horizontal or vertical position. In addition, material discrimination Zeff and air spatial resolution is being tested.

Universal Test Piece (Any OEM)

One Pass

Accurate Rotatable Mechanism

Additional tests includes Material Discrimination (Zeff) Air resolution (see value proposition ANSI 42.46)

Designed especially for medium x-ray tunnel size greater than 1mx1m

9 Comprehensive Test

- Test 1 Resolution Test

Image Quality Indicator, IQI on sharpness and blurring of copper wire images in air and behind concealment

- Test 2 and 3 Material Discrimination Air

Organic test of several thickness of explosive surrogate in air

- Test 4 Contrast Sensitivity

Contrast is the measure of density difference between 2 areas. Easier to distinguish features of interest amongst its surrounding. The lower the sensitivity level the better

- Test 5 Material Discrimination Steel

Contraband and explosive test behind steel concealment

- Test 6 Spatial Resolution

The ability of image system to differentiate between 2 nearby objects. Typical thickness ranges from 2mm to 0.5mm

- Test 7 Material Discrimination

4 types of materials with various thickness are tested ranging from aluminum to organics

- Test 8 Spatial Resolution Concealment

- Test 9 Penetration

The level of penetration of system eg 25mm to 75mm steel